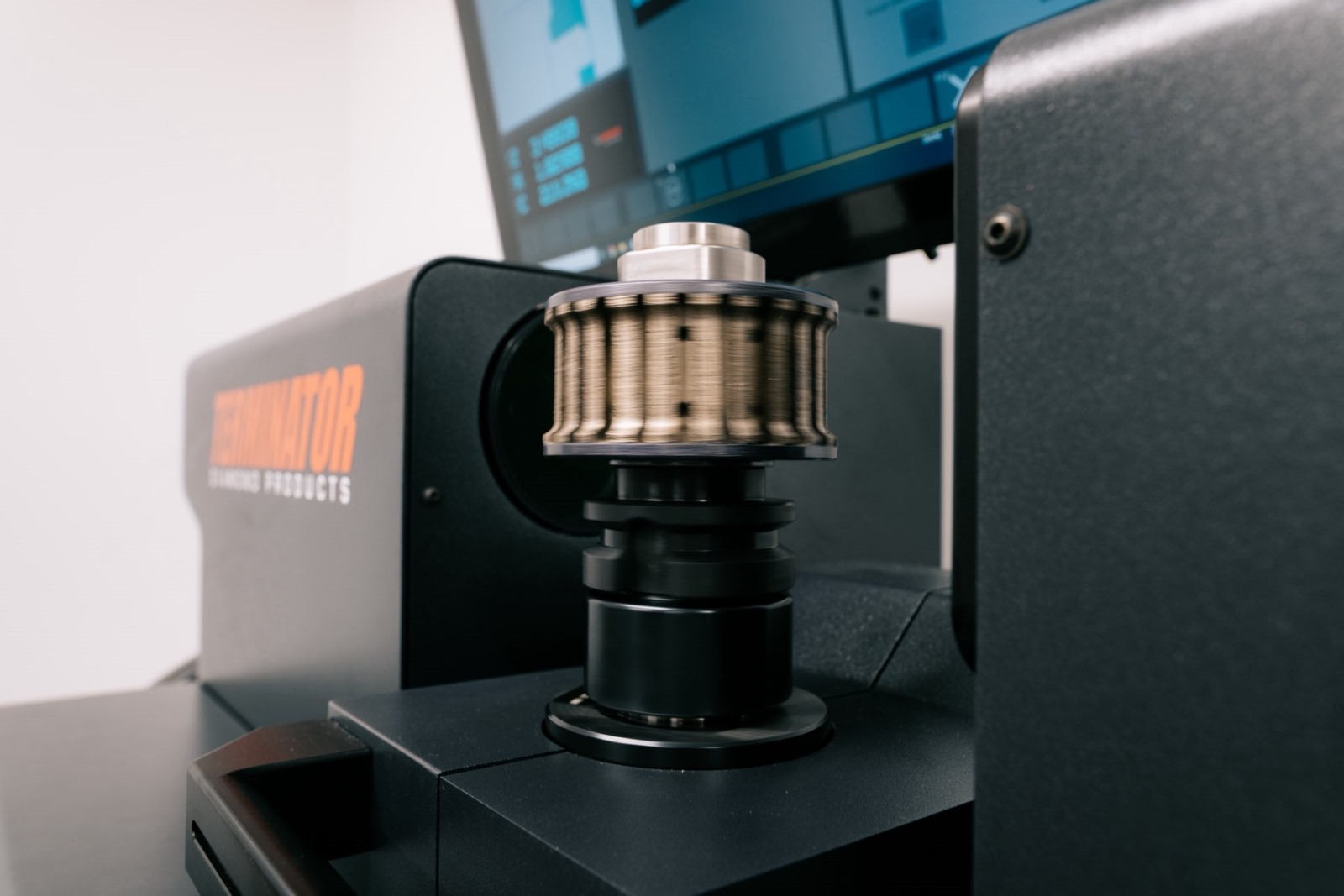

Tooling Is Not a Consumable — It’s a Strategy

Tooling Is Not a Consumable — It’s a Strategy

In many fabrication shops, tooling is treated as a line item; something to purchase, use, and replace. But in reality, tooling is one of the largest capital investments in a fabrication facility and one of the most influential drivers of uptime, consistency, and profitability.

It’s time to rethink how we approach tooling, not as a consumable, but as a performance system.

Why Tooling Strategy Directly Impacts Shop Performance

Why Tooling Strategy Directly Impacts Shop Performance

Tooling decisions affect far more than cut quality. They influence:

- CNC uptime

- Throughput speed

- Programming consistency

- Labor efficiency

- Rework rates

A direct tooling program with safety-net stock can significantly reduce downtime. Tool branding, bond hardness, and speed compatibility all impact how efficiently your CNC machines run.

Yet one of the most common mistakes shops make is minimizing maintenance programs to reduce labor spend. Tooling is often the second-largest capital investment in a fabrication facility. Hoping tools continue to perform at peak output without structured maintenance is like expecting employees to thrive without support or development.

Performance doesn’t happen by accident — it’s managed.

The Problem With “Good / Better / Best”

Many shops approach tooling with a “good, better, best” mindset, searching for a unicorn tool that solves every problem.

That unicorn does not exist.

Believing you’ve found the “best” tool can actually hurt performance if it doesn’t align with your shop’s system, programming style, culture, or production flow. Brands matter less than partnership and application.

Instead of focusing on price tiers or brand loyalty, shops should focus on:

- Using tools at the correct parameters

- Matching tooling to material type

- Following recommended speed and feed rates

- Ensuring proper application

Performance and longevity come from proper utilization, not simply purchasing a premium label.

What Actually Drives Tool Life and Cost

Across fabrication shops, two factors influence tooling performance more than anything else:

- Utilization

- Maintenance

Using the correct tool on the correct material, with the correct speed and feed rate, is foundational. That includes recognizing that granite and quartz tooling may not perform the same way on quartzite or ultra-compact materials.

Using the wrong tool for the application is like using a screwdriver to hammer in a nail. The cost increase isn’t the tool, it’s the process error.

Assuming other shop conditions are properly managed (water flow, substrate stability, airflow/CFM), tooling performance largely depends on how disciplined your system is.

Aligning Tooling With Shop Reality

Tooling programs should evolve with:

- Production volume

- Machine count

- Job mix

As output increases or decreases, your tooling system should adjust, but complexity doesn’t need to mirror production growth. A well-structured, active program with machine-exchangeable opportunities can protect revenue and reduce downtime.

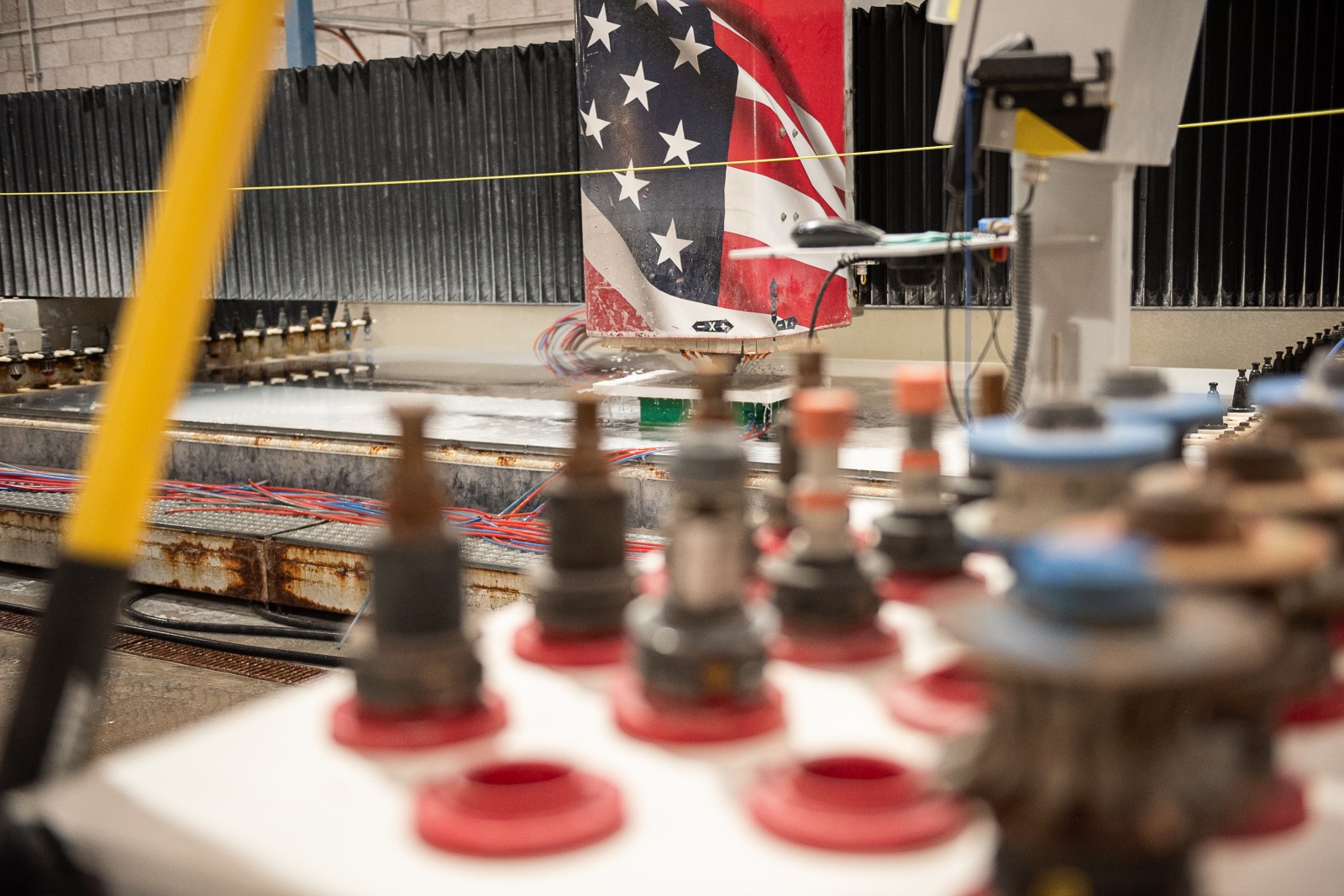

Standardization also plays a critical role.

When shops use multiple brands with different bond structures and performance characteristics, maintenance becomes inconsistent. Programming styles shift. Tool response varies. The “norm” of how tools behave disappears.

Standardization restores predictability, and predictability reduces downtime.

The Hidden Cost of Running Tools to Failure

Of course, shops want maximum life from every tool. But running tooling until failure often creates:

- Rework

- Remakes

- Machine damage

- Production delays

Overleveraging tooling may seem cost-effective short term, but it increases risk and unpredictability.

Defined usage rates and replacement intervals create reliability. Replacing tooling “off the hip” leads to budget instability and quality inconsistency — and may force shops to use worn tooling on high-performance jobs, resulting in lost opportunity.

Every shop needs a defined system. Discipline protects margin.

Fabricating Demanding Materials With Confidence

Materials like quartzite and ultra-compact surfaces often create hesitation. While they carry strong gross margins, they also introduce fabrication challenges, slower throughput, increased break rates, and higher stress on equipment.

Some shops simply avoid them.

However, with proper tooling innovation, training, and vendor partnership, these materials can be fabricated with far greater reliability, without major process overhaul or cultural disruption.

The key is selecting a tooling system designed specifically to handle these challenges. Partnership with a knowledgeable vendor is often more important than brand preference.

Visibility Changes Everything

When shops lack visibility into tool condition and usage, problems compound:

- Declining quality

- Increased remakes

- Machine strain

- Damaged reputation

Tool performance is a foundational pillar of quality. Poor visibility weakens that foundation.

Better tracking and measurement transform decision-making. When labor rates and fabrication performance become measurable KPIs, leadership gains analytical insight into profitability. At the same time, transparency helps employees understand their role in overall company success.

But measurement only works in the right culture. Accountability and buy-in matter.

The Mindset Shift That Changes Results

Tooling performance ultimately comes down to belief and direction.

If a shop looks only at tooling through a financial lens, decisions become transactional. But fabrication has a human component, trust in systems, confidence in partners, and belief in forward momentum.

When financial discipline and trust in a strategic direction align, transformation happens.

One Practical Step You Can Take Today

Dress and measure your tools religiously. Period.

That single discipline can immediately improve consistency, extend tool life, and protect quality.

Tooling isn’t just something you buy.

It’s something you manage.

And when managed strategically, it becomes one of the most powerful performance drivers in your shop.