Is Your Water System Holding Your Shop Back? 7 Signs It’s Time to Upgrade in 2026

Is Your Water System Holding Your Shop Back?

7 Signs It’s Time to Upgrade in 2026

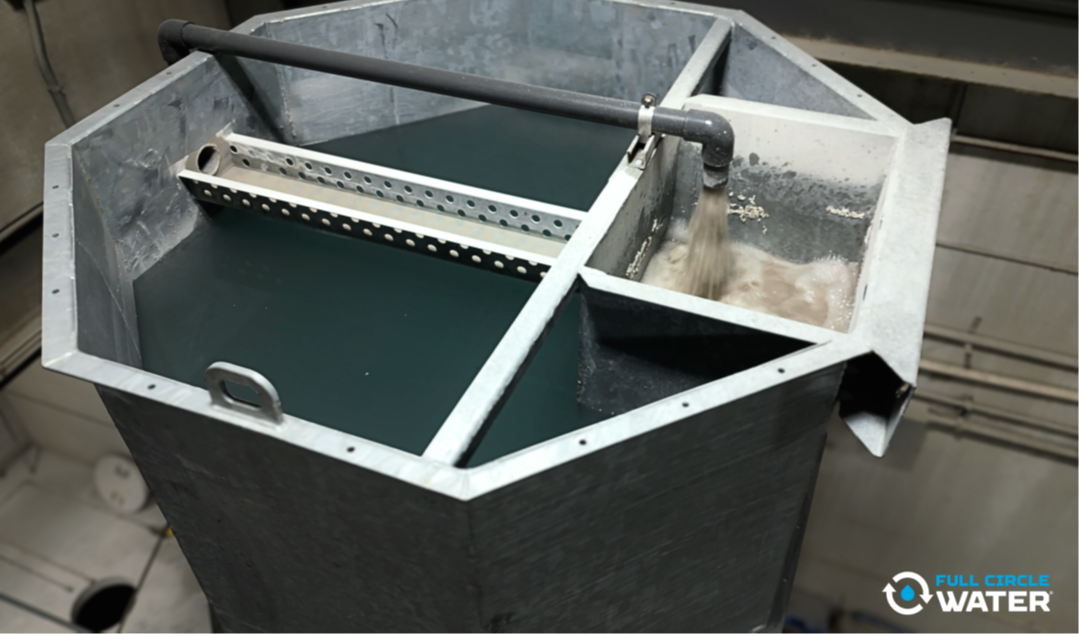

In today’s countertop fabrication shops especially those cutting engineered stone your water system isn’t just another piece of equipment. It’s the backbone of your shop production. Your countertop quality, equipment and tool life, employee safety, and compliance are all affected by water quality.

Many shops don’t realize their water system is slowly dragging down efficiency until problems start stacking up: cloudy recycled water, premature tool wear, unhappy installers, or worse silica compliance issues.

If you’re unsure whether your current setup is helping or hurting production, here are seven clear signs it’s time to upgrade your water recycling system in 2026.

1. Your Recycled Water Isn’t Clean

If the water feeding your saws, routers, edgers, and polishers looks like a latte instead of relatively clear water that’s a problem.

Why it matters: Cloudy water is loaded with micron-sized silica particles. These particles don’t just reduce equipment performance they reintroduce silica back into your process, creating:

- More airborne silica dust when it dries

- Increased filter changes

- Heavier wear on pumps and spindles

Rule of thumb:

If you don’t like getting water on your hands from your recycled water lines, its likely not in a good condition for your shop, your equipment, and your employees.

2. Tools Are Wearing Out Faster Than They Should

Diamond tooling isn’t cheap. But if you’re replacing tools more often than expected, your water system may be the hidden culprit.

Dirty or under-filtered water acts like liquid sandpaper. That abrasive slurry accelerates wear on:

- Blades

- Polishing pads

- CNC tooling

- Bearings and seals

A clean water system pays for itself simply in extended tool life.

3. Your Slurry Management Feels Out of Control

If you’re battling:

- Thick sludge building up in trenches

- Frequent pump failures

- Labor-intensive cleaning days

- Floors that constantly feel gritty

…your system isn’t removing solids efficiently.

In 2026, modern systems use better separation, flocculation additives, and higher-capacity filtration to keep water clean and sludge manageable. The right system reduces both labor and downtime.

4. Production Slows Down or Stops When WaterDemand Spikes

As your shop grows, your water system needs to grow with it.

Signs your system is undersized:

- Cutting speed drops during peak operations

- Flow to polishers becomes inconsistent

- CNC machines alarm due to low pressure or flow

- You run out of filtered water

- Pumps cycle constantly

If you’ve added machines in the last 3–5 years without upgrading your water system, this is almost guaranteed to happen.

5. Your Team Complains About Dirty Finishes

Technicians are often the first to notice when water quality is slipping. They may report:

- Scratched surfaces

- Hazy polishing

- Slurry buildup on fixtures

- More rework than usual

If your crew keeps saying, “Something’s off,” listen. Their tools and finished edges are telling you the same thing.

6. You’re Worried About Silica Compliance

Silica regulations aren’t getting looser if anything, 2026 is bringing more inspections and stricter accountability across fabrication shops.

A poorly performing water system can affect compliance by:

- Allowing fine silica particles to remain in the water

- Producing hazardous dried slurry

- Causing visible dust during cleanup

- Increasing exposure risks during tank cleanouts

- Not having enough water to properly wash down the facility as needed.

Clean water = safer shop.

Dirty water = potential citation.

7. Maintenance Feels Like a Full-Time Job

Your water system should not be the shop diva constantly demanding attention.

Recurring pain points include:

- Pumps burning out

- Filters clogging daily

- Settling pits overflowing

- Tanks filling with sludge

- Needing constant manual intervention

A modern system is designed to reduce labor, not consume it.

If your crew spends more time wrestling the water system than running machines, it’s time to rethink the setup.

What an Upgraded 2026 Water System Should Deliver

If you’re considering an upgrade, look for:

- Clean recycled water

- Consistent flow and pressure for all equipment

- Automation to reduce labor and downtime

- Effective slurry separation

- Easy maintenance with accessible components

- Compatibility with slurry additives (like Great White)

- Scalability as your shop grows

The right system pays dividends through:

- Better production consistency

- Longer tool life

- Less downtime

- Cleaner workstations

- Improved safety

- Happier operators

Final Thought: Don’t Let Water Become a Bottleneck

In 2026, competitive shops are investing in clean water as a strategic advantage. Dirty or inadequate water isn’t just a nuisance it’s a silent drain on profits, safety, and workflow.

If your current system is showing any of these seven signs, it’s probably holding your shop back. The good news? Upgrading is one of the simplest ways to boost productivity overnight